The electric vehicle (EV) market continues to grow, not just for consumers, but also for fleets. Many applications are proving to be excellent uses for EVs such as mowers, tractors, and utility trucks. Fleets that can take advantage of on-site charging such as warehouse forklifts and airport ground support are often ideal candidates for EV adoption.

Companies that are interested in converting their fleets to EVs are watching the market for available vehicles that meet their requirements. By anticipating EV fleet electrification needs, OEMs can meet the demand for vehicles that perform.

Custom rubber formulations play a key role for EV manufacturers in multiple ways:

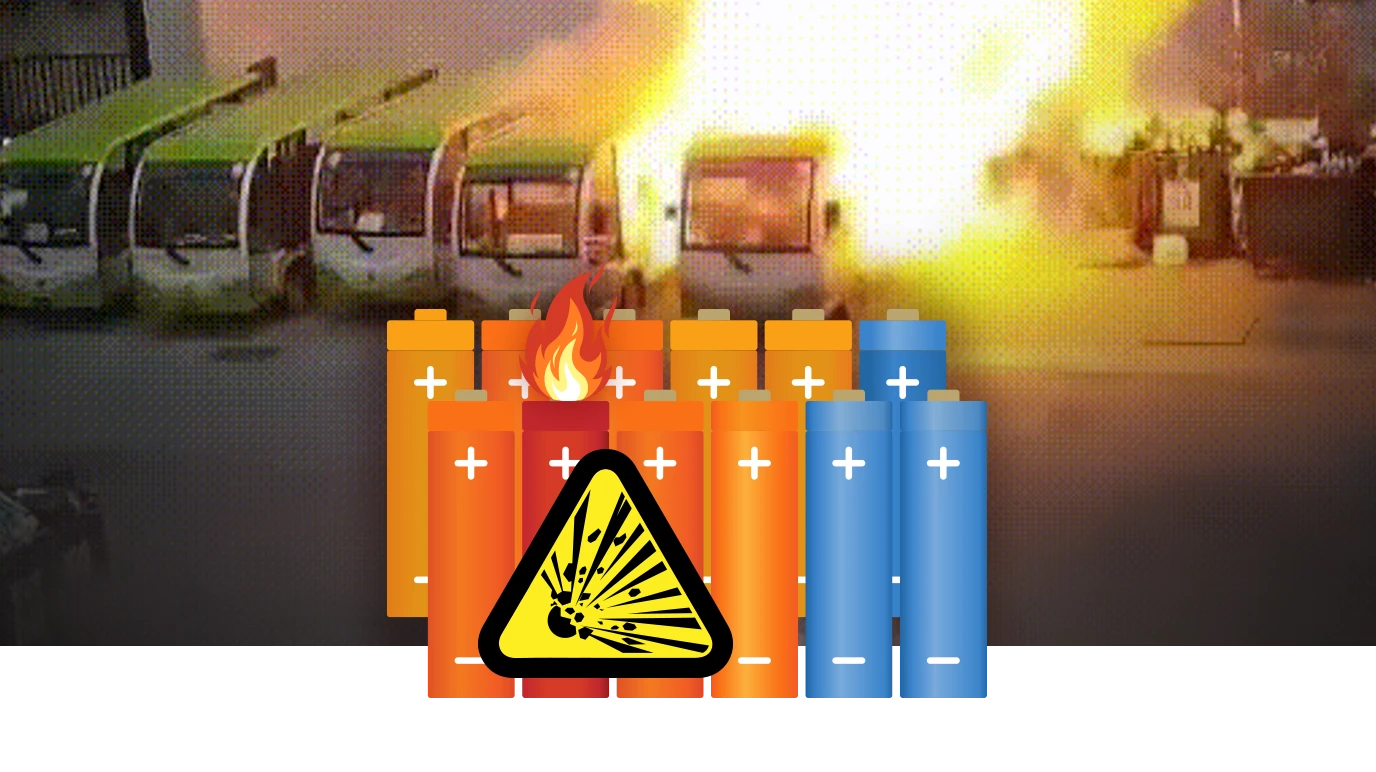

- Mitigating risks associated with thermal runaway events

- Optimizing efficiency and improving performance

- Peeding time to market and scaling up production

Find out how rubber solutions can be custom-engineered to enhance electric vehicle design and manufacturing!