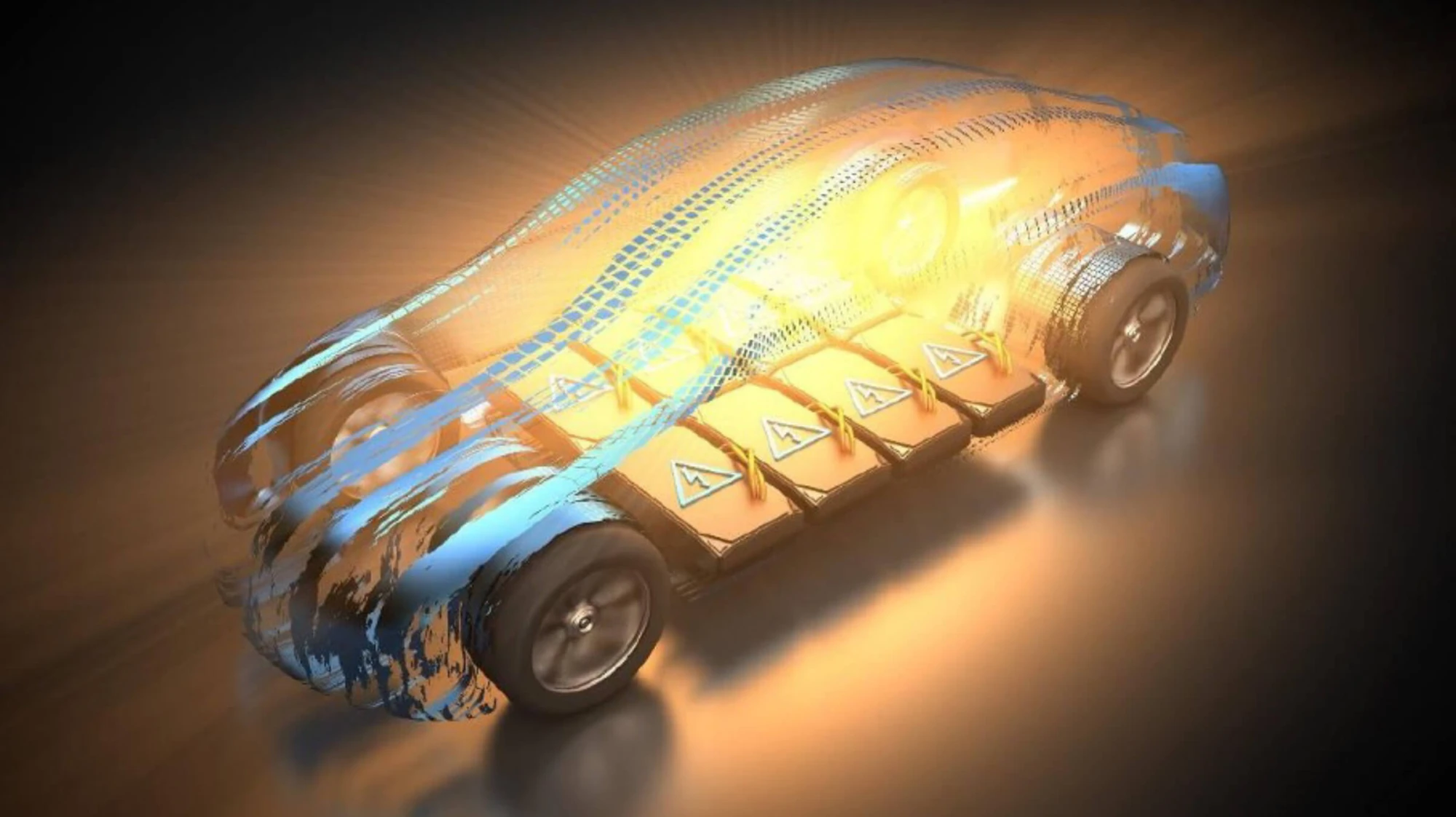

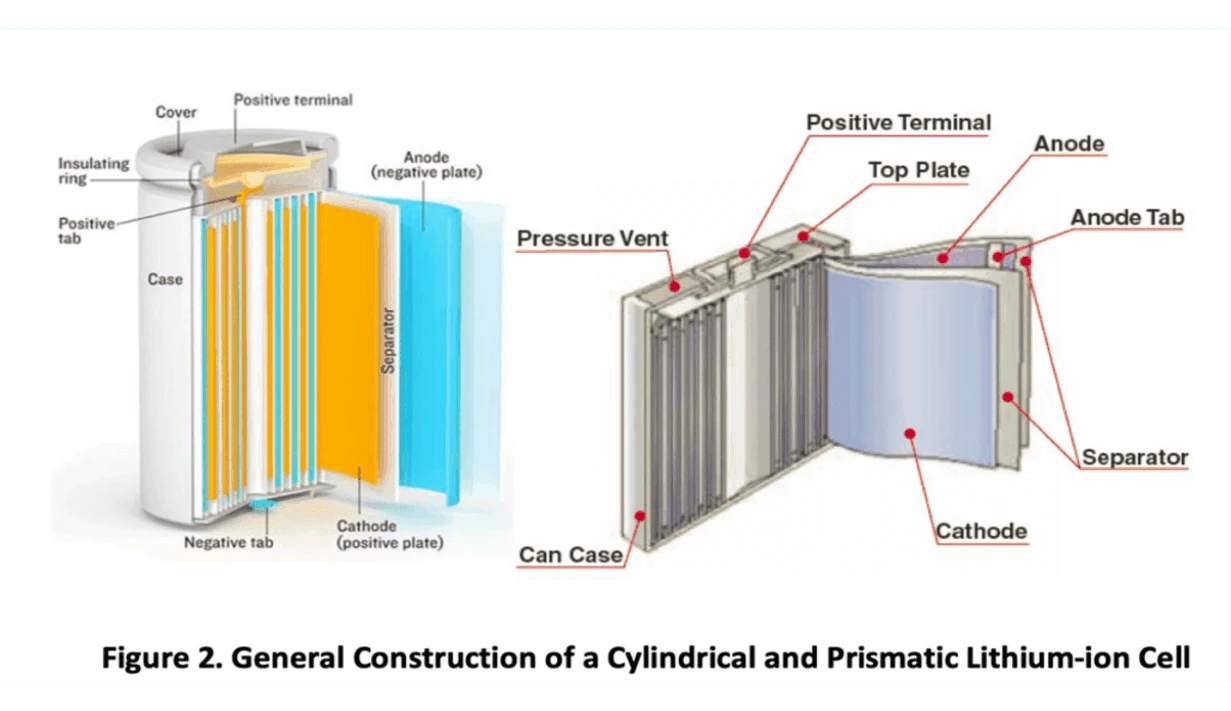

As the electric vehicle (EV) market continues to grow, thermal events are a major point of concern with lithium batteries. Preventing damage is extremely important to preserve the internal chemistry and heat dissipation capabilities of batteries and battery cells. By damping noise and vibration, custom-engineered rubber solutions offer mechanical protection for batteries in electric vehicles. Let’s take a closer look at what a thermal runaway event is, and how to minimize the risk.

Soucy Baron is not simply a manufacturer of elastomer parts; We are an end-to-end logistics partner, dedicated to the success of your project above all else. Working with Soucy Baron means you’ve got a partner who understands your challenges.