On the financial health balance sheet for farms, fuel is a significant contributor to costs. Many pieces of agricultural equipment use diesel-powered engines:

- Tractors

- Combines

- Harvesters

- Transport trucks

- Pumps

Any opportunity to reduce fuel consumption can help farmers move closer to breaking even and profitability. Keeping machinery well-maintained is common advice to help minimize fuel costs, as well as using more efficient equipment.

In their mission to help farmers reduce their operation costs, manufacturers are designing innovative new equipment with improved fuel economy. In the quest for efficiency, every component counts. Seemingly small adjustments and improvements add up over the course of a vehicle’s lifetime for significant fuel-conserving benefits.

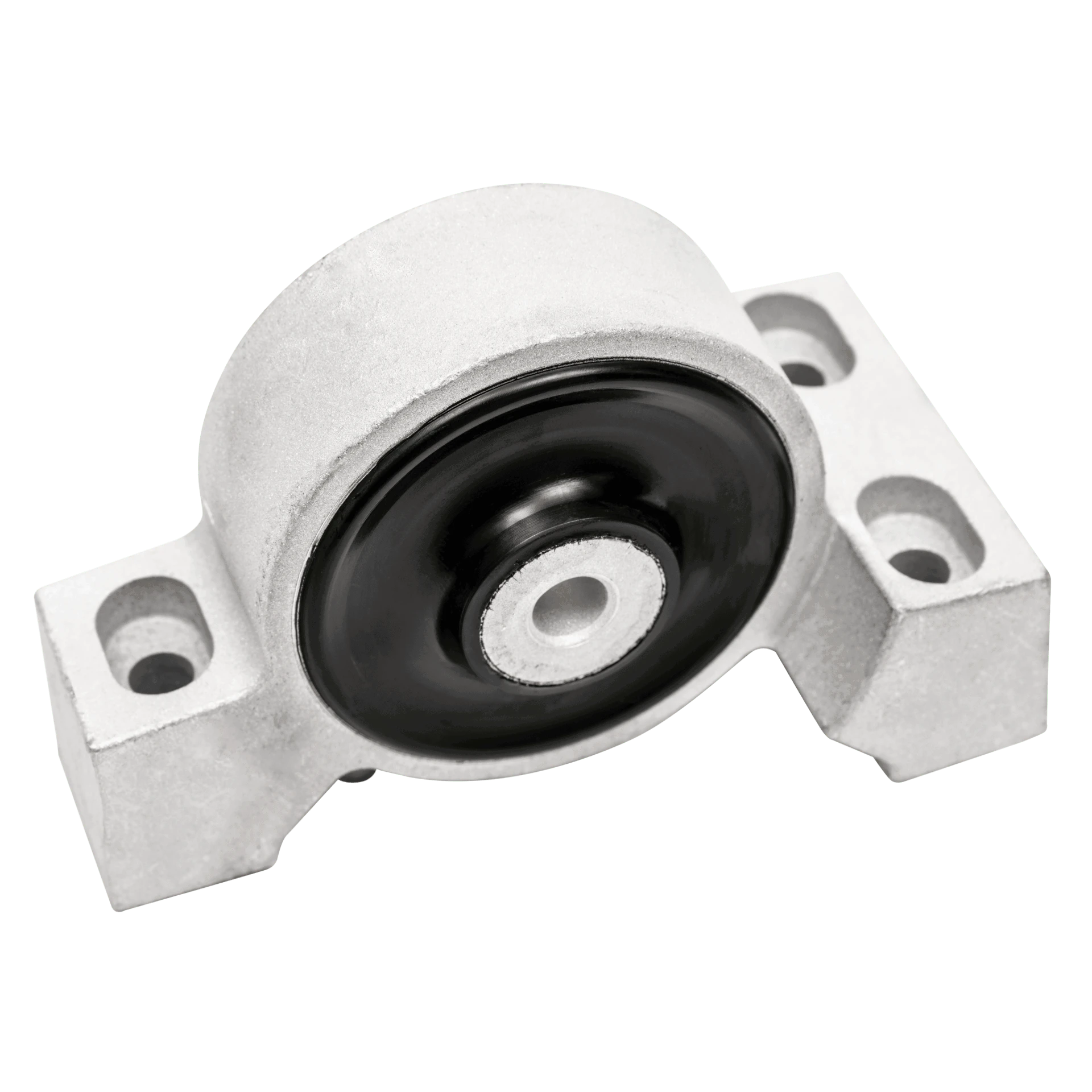

Thanks to its unique properties and ability to dampen vibration, rubber has a significant role to play in improving engine efficiency in agricultural vehicles. Let’s take a closer look at how rubber components can mitigate issues that affect fuel consumption in agricultural equipment.