At Soucy, our top priority is to foster a safe and ergonomic work environment, both in our offices and at our manufacturing plants. As proof of our dedication to ensuring the health and safety of employees, Soucy Plastiques has recently integrated state-of-the-art equipment into a new bonding cell that was meticulously designed with optimum ergonomics in mind.

The rising need for large-scale bonding

The project was a response to a very specific need: overmoulding rubber onto heavy, bulky rims. At the request of a client, the team at Soucy Plastiques decided to carry out this step of the manufacturing process themselves, thereby guaranteeing the superior quality of the end results.

Designing safe, high-performance equipment

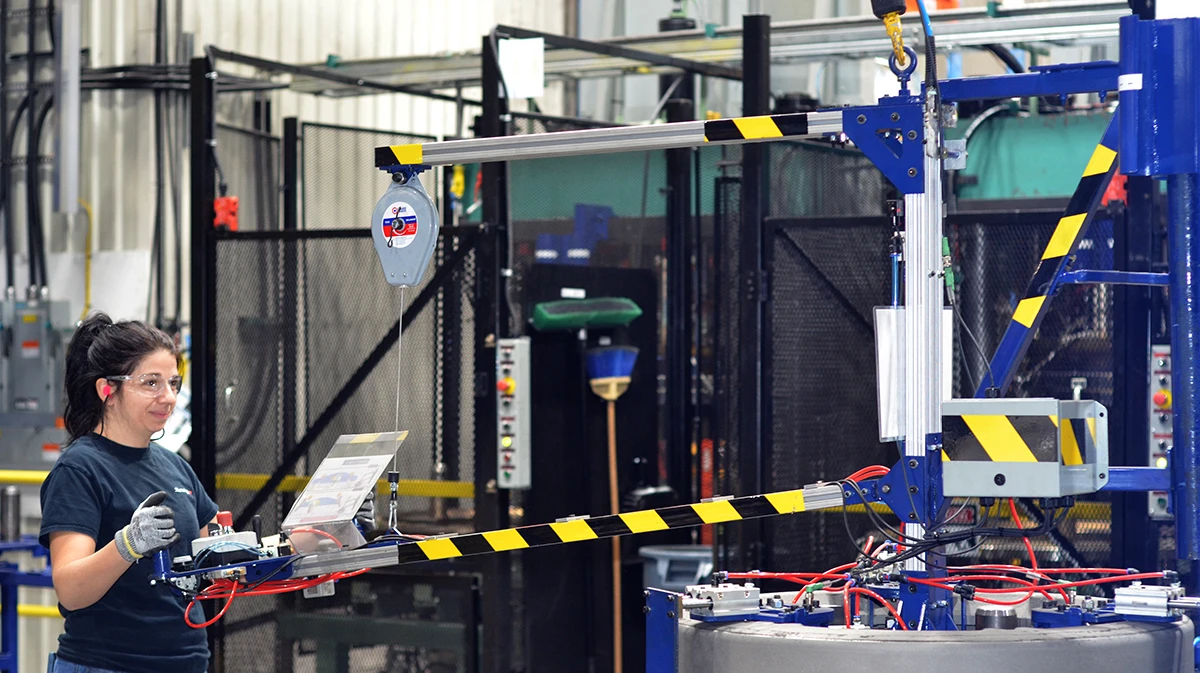

In order to design customized equipment, the team in charge first needed to conduct a detailed analysis of the project’s needs and constraints. One of the objectives was to produce a manipulator to help employees transport 250 lb. rims with overmoulded rubber. To ensure a safe work environment, ergonomics remained front and centre throughout the entire process.

The ergonomic manipulator allows employees to remain a safe distance from parts that can reach temperatures of more than 120°C. It also allows each person to personalize the way they operate the equipment. The person controlling the manipulator steers a rim held in place by a cable; the handling process is fluid and does not require any physical exertion. In fact, the project team received very positive feedback from employees who were thrilled to work with a tool that makes them even more efficient.

Training – a key component of the project

Even before the project began, the team at Soucy Plastiques was committed to guaranteeing the safety and well-being of employees. As such, they underwent an in-depth training course on ergonomics which enabled them to implement the best ergonomic practices throughout the development process. Carefully applying recommendations has meant that all employees can benefit from a safe and comfortable working environment.

Once the cell was complete, trial sessions were carried out. Operators tested every aspect to make sure it was safe and efficient. As a testament to the expertise and flexibility of the team at Soucy Plastiques, every step of the project was carried out internally.

Safety at the heart of the value chain

In addition to making sure the cell was safe for our employees, we also kept our external partners in mind. For instance, Soucy Plastiques created reusable packaging that can be used for transporting parts and as a work platform. Once the subcontractor receives the package, they can work on the rims directly on the pallet. That means no more handling these heavy parts. And once the work is done, the packaging is sent back to Soucy Plastiques where it will be reused to transport other finished products to the client. It’s an efficient way to reduce the risk of injury while doing more for the environment!

The new bonding cell at Soucy Plastiques is proof of our unwavering dedication to the well-being of employees. By leveraging the best ergonomic practices at every step of the process, the team at our subsidiary in Drummondville have demonstrated their drive for innovation and profound commitment to providing a safe, productive work environment. This initiative reflects our core values and strengthens our position as one of Quebec’s largest manufacturers.

This article was written by Soucy Plastiques