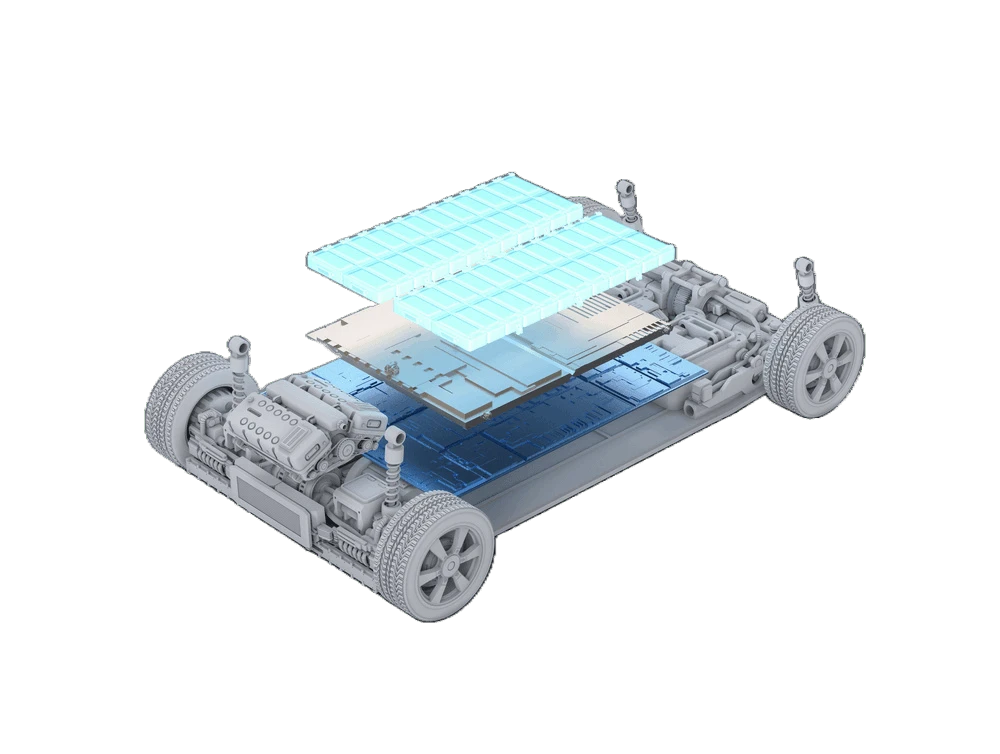

As battery technology evolves and advances such as successful battery swapping make the use of batteries in off-road vehicles more advantageous, OEMs are developing fully electric and hybrid models to meet customer demand and sustainability goals.

The battery-powered off-road vehicle market needs innovative solutions not just from vehicle manufacturers, but also from companies that play key roles such as those that make battery testing equipment and automation. Everyone in the battery industry needs partners that are actively investing in R&D, and have the expertise and equipment needed to develop innovative solutions.