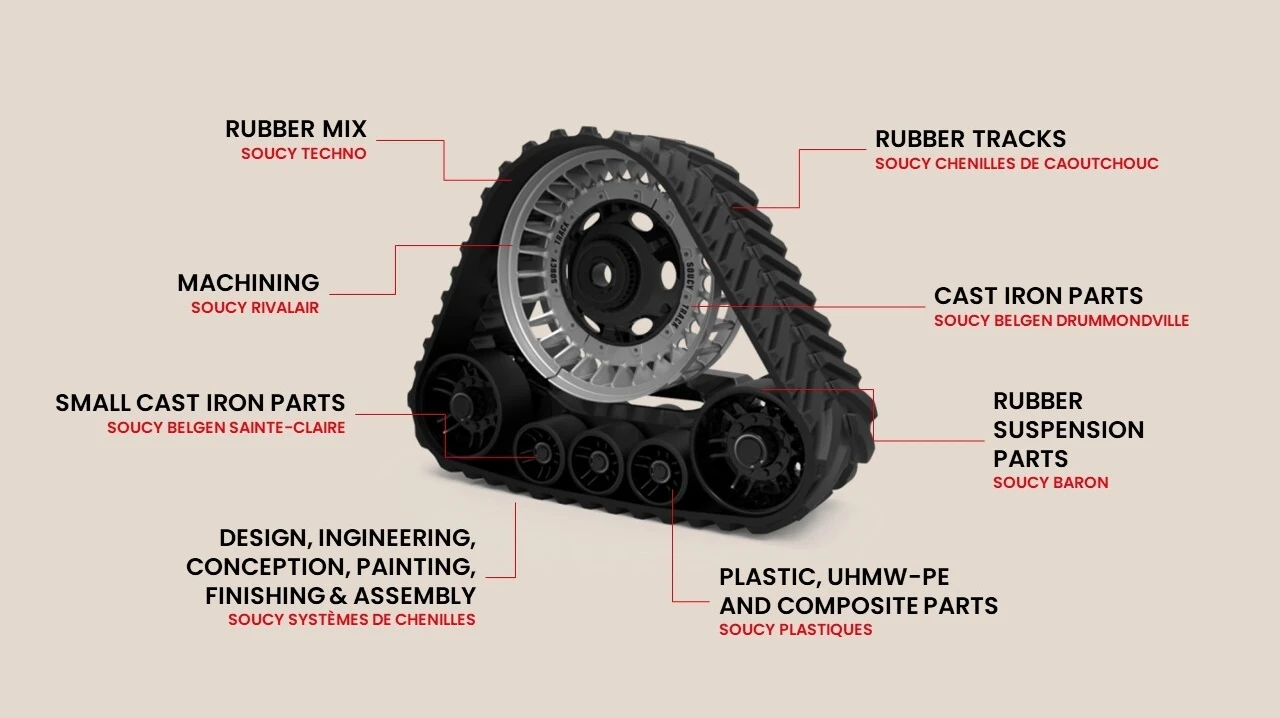

Our company comprises myriad expert units that combine their skillsets to create a flagship product of the off-road industry: the Soucy track system. Thanks to our efficient vertical integration strategy, every step of the development and production phases – from design to manufacturing – is carefully aligned. The synergy between our units enables them to efficiently combine their expertise and know-how to provide our clients with turnkey solutions.

The benefits of this efficient strategy focused on collaboration