All O-rings Are Not Created Equal

Several factors impact their performance, durability and ability to function effectively in challenging environments.

Several factors impact their performance, durability and ability to function effectively in challenging environments.

Engineered and developed entirely in-house, this robotized bonding system achieves high precision applying adhesive to reinforcement inserts prior to rubber molding.

Discover how combined rubber enhances motorized equipment performance. Analysis of benefits, applications and innovations for the powersport sector.

OEMs often focus their attention on using automation and technology to reduce labor costs; however, bill of materials (BOM) expenses are also a significant source of cost reduction.

Discover how rubber is revolutionizing electric vehicles in motorsports. Innovative solutions for battery protection, acoustic insulation and optimal performance.

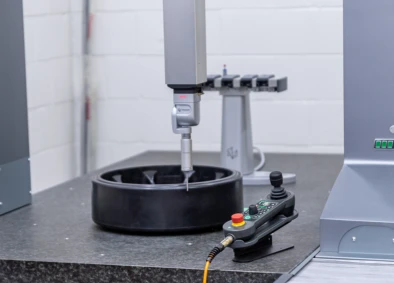

Discover how CMM technology revolutionizes precision measurement for rubber parts. Advanced quality control, guaranteed accuracy, and optimal traceability.

Technology gives farmers the ability to monitor their crops in real time, optimize their operations and improve productivity.

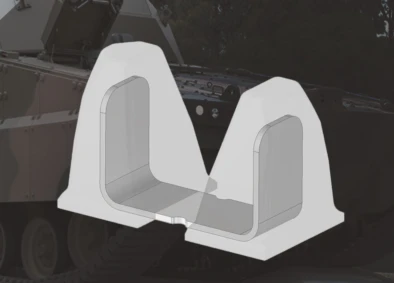

Learn how Soucy Baron engineered advanced double reinforcements for military tracks, delivering exceptional durability and performance in extreme environments.

Factory robotization: an ally for worker safety and efficiency. Discover how automation enhances working conditions and productivity.